Reproducible quality at highest ROI, easy operation and highest flexibility

The EBSO SPA 440-EVO / SPA 550-EVO is the most transparent and flexible selective soldering system on the market. Developed for practitioners. 100% Made in Germany. 100% precision.

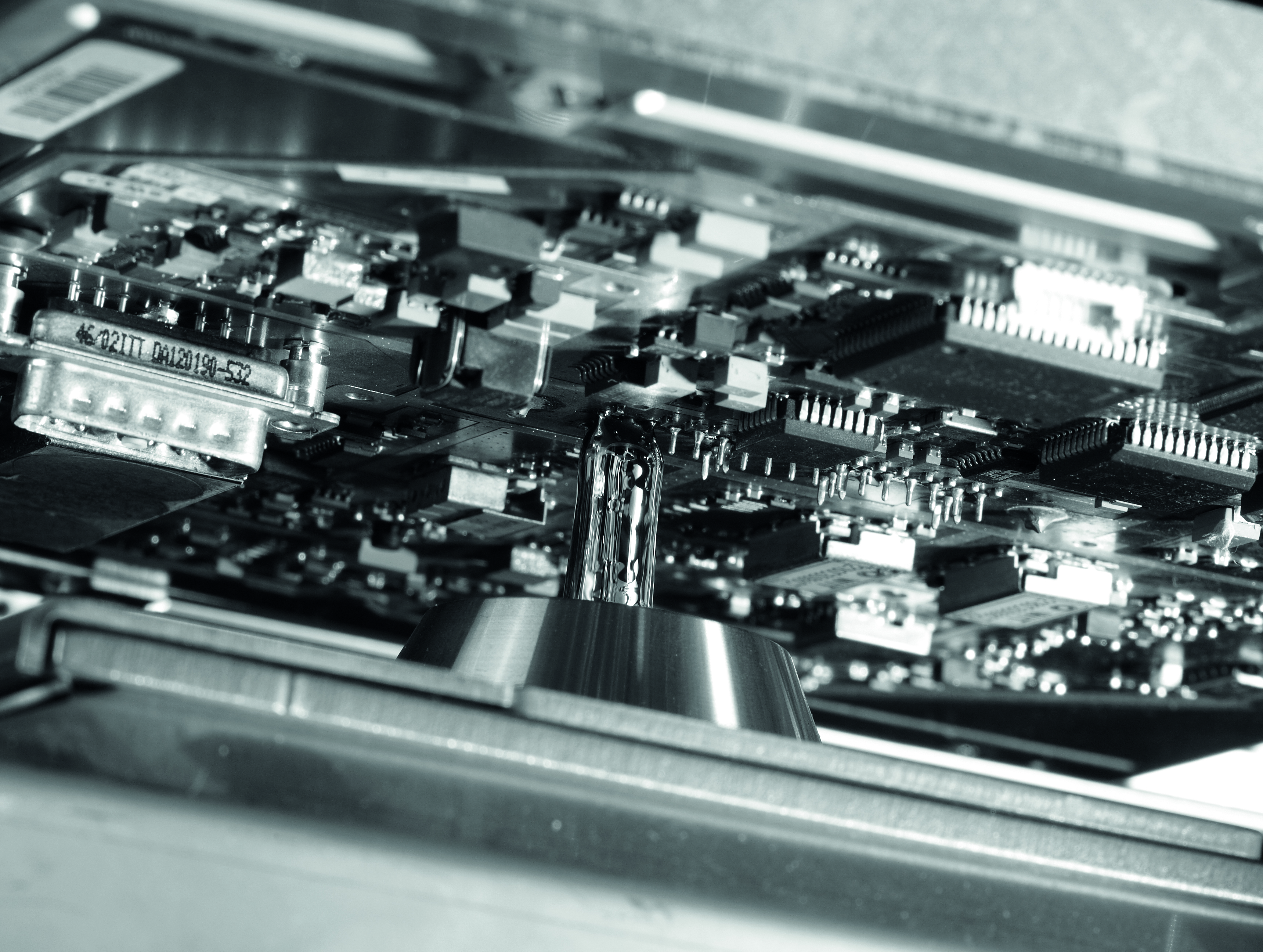

The xyz-axis system positions the assembly over the Microdrop Fluxing Unit, the pre-heater and the solder module. Everything is mounted on a leveled working area, which gives the SPA its unrivalled transparency and maintenance friendliness.

The EBSO-Concept offers you the capability to flux or solder two assemblies simultaneously and in consequence the best ROI due to the outstanding through put/footprint ratio.

The with nitrogen fumigated high quality titanium solder pot and the titanium solder pump unit warrant extreme longevity and are best fit for any solder alloy including leaded tin. The unique EBSO FAST REMOVE MECHANISMS make sure you don’t waste any time for daily routines.

The EBSO SPA excels on maximum availability at minimal maintenance expenses. The open and tidy working area provides best accessibility and visibility for process observation and maintenance.

EBSO offers a wide range of solder nozzles in different heights, diameters and geometries. Be it wetable or non-wetable nozzles. At request we design and manufacture customized nozzles in any shape or form, in order to increase your through put to the absolute maximum.

The EBSO Offline Editor is the SPA-EVO programming software which enables you to program every flux and solder point with relaxing ease. Simply point and click on the graphical interface and you are almost good to go.

On top of that we offer a wide range of top notch options in order to improve your cycle times, your process security or the utility.

Features:

High quality steel welded construction

Stabiles hochwertiges Schweißgestell

ESD powder coating

Space saving glass gull-wing doors

Huge storage space for accessories and maintenance material

Two level WERMA signal light

Light grid (Security)

Solder level

Solder temperature

N2 flow

N2 pressure

Air pressure

Flux level control

Maintenance message

Solder wave height control (optional)

Flux application control (optional)

Solder fixture recognition (optional)

Exhaust air sensor plug&play (optional)

3 pcs nozzle tips. Wetable without coating and repairable!

1 pc nozzle socket for tips

1 pc universal solder fixture. Milled out of one piece for highest precision

Nozzle key

Pump key

Solder utensils

USB-Port for barcode reader for program selection

D-SUB-Connector for placement of additional start button

Exhaust air sensor communication

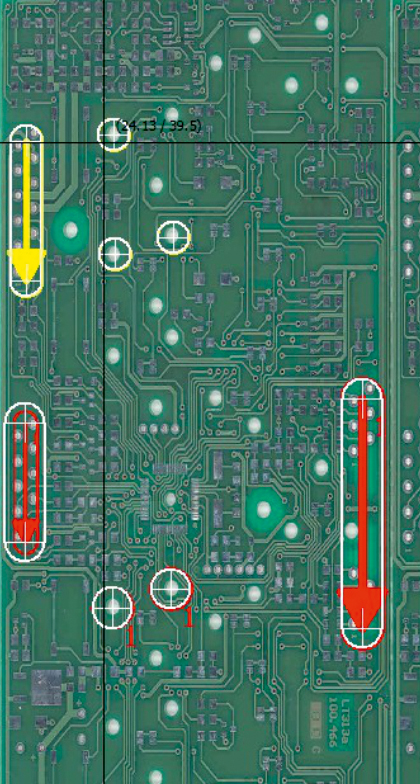

Programming the SPA

Offline Editor incl. Import functions and Picture Editing

Easy point & Click Offline Programming if solder programs. Nos production Free adjustments of all solderparameters.

Entering of solder positions with simple meassuring of X and Y position of Solderjoint or via

Import of CV Data of i.e. Drill Gerber Datas. Simply scan a bare PCB. Point and Click on the image where you want to solder.

The software automatically calculates the correct X and Y coordinate.

Advantages

You see the PCB on the image thus you can instantly consider neighbour SMD Components and enter the solderpoint according to your nozzle size.

No complicated and and expensive teach-in camera is necessary.

You can't have programming much easier.