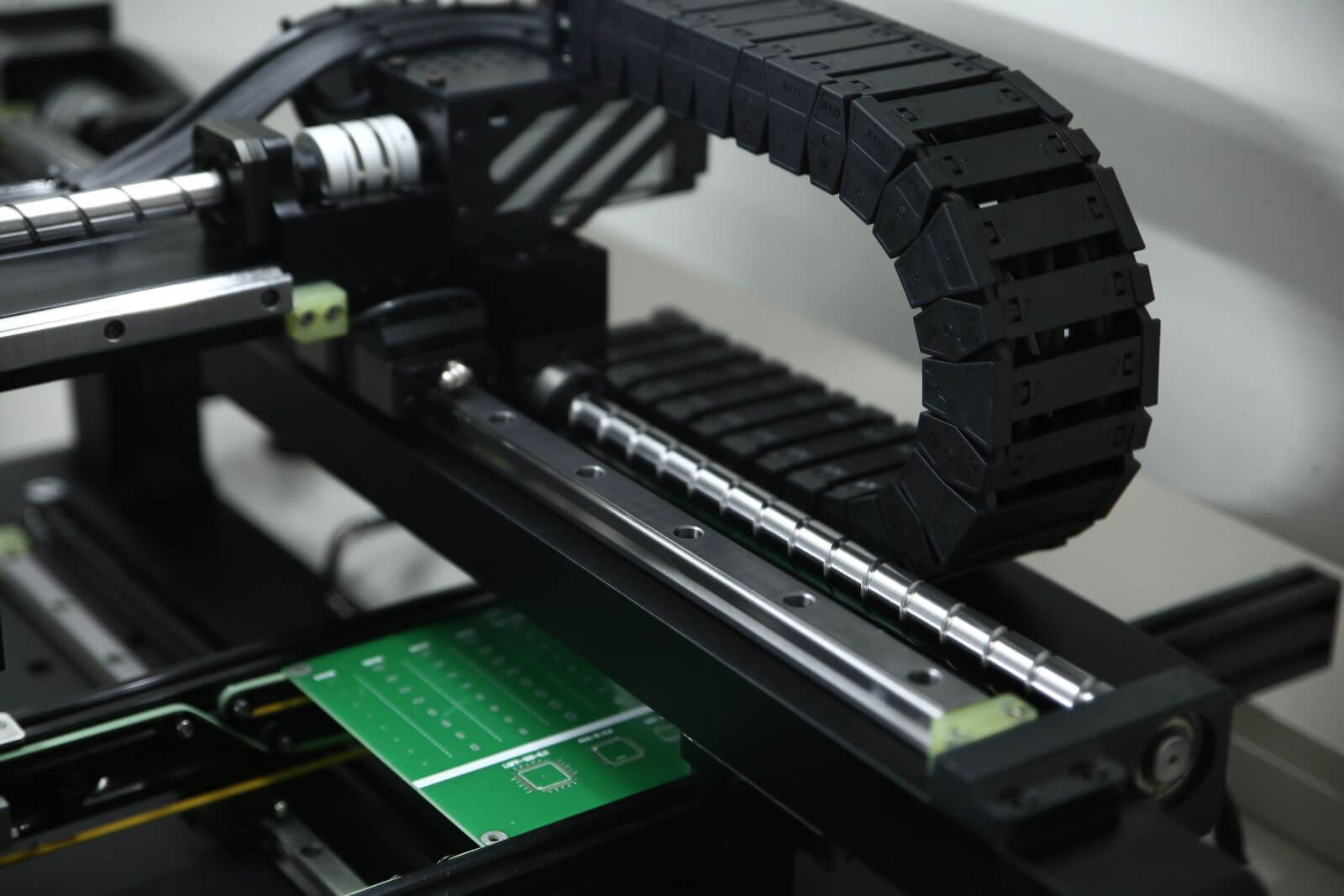

Desktop automatic pick&place machine of SMD-components on the surface of PCB's

KAYO A2 and A4

KAYO A2 and A4

KAYO A2 and A4

System features:

| The presence of four cameras to recognize and pick&place the components at high speed; | |

| High speed and accuracy of pick&place of components; | |

| Simplicity and ease of operation and maintenance. |

| Number of feeders 8 mm | 46 pieces |

| Feeders: | 8/12/16/24/32 mm, vibration feeders |

| Number of mounting heads: | 4 pieces |

| Mounting accuracy: | ±60 μm (3σ) |

| Drivers: | servomotors Panasonic + ball screw + X/Y linear guides |

| Modes: | manual, semi-automatic, automatic |

| Max placement speed: | 7000 comp/hour |

| Max axis movement Z: | 20 mm |

| Max dimensions of the PCB: | 480х300 mm |

| Mounted components: | from 0402 to 40х40 mm, LED, QFP, BGA step outputs ≥ 0,3 mm |

| Max component height (Z): | 5,5 mm |

| Monitors: | 15" |

| OS: | Windows |

| Programming: | data conversion, step by step, visual |

| Power supply: | 1 phase, 220 V, 50 Hz, 600 W |

| Pneumatic pressure: | 5 - 6 Bar |

| Machine dimensions: | 1180x1080x880 mm |

| Machine weight: | 240 kg |

| Quick release connector: | Ø 10 mm |

Pictures

KAYO VIDEO