• 25MP high speed Industrial camera & High resolution Lens

• Graphic programming, easy to programming

• There is a barcode reader inside, every products are storied with the barcode information, the inspection data is traceable

• SPC data can be carried out which can provide data support for the improvement of quality and process improvement

• Real time monitoring of production line , no need stop when inspection,the inspection is finished when the board passing

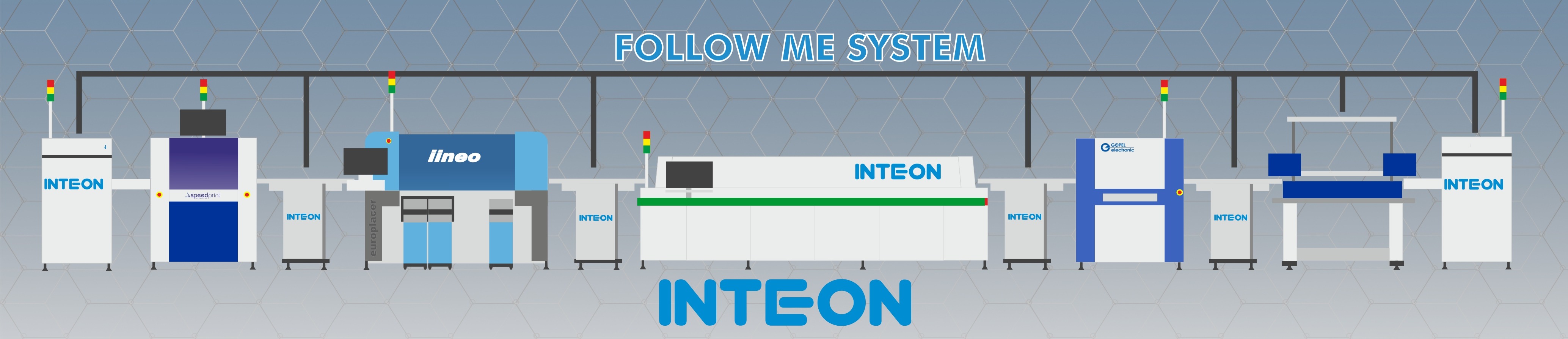

• All production line equipment can be centralized management through the central server, also can collect all the test data and information of the production line, convenient for the management.

Wrong insertion, missing, offset and reverse of DIP process components (obvious polarity mark on the top of components)

Fixed bar code identification device, can identify 1D/2D bar codes (optional)

PCB Size 50*50mm~450*450mm

Height of Components TOP≤80mm

The test data can be analyzed in SPC software interface and output report in Excel format

Outsize of Machine(L*W*H)

1494*1900*847mm (without foundation and signal lamp)

Weight ~250kg