Multi Line can fully display its flexibility when inspecting THT assemblies. On the one hand, different camera modules can be used for 3D measurements or for the inspection of very tall components. The system allows transport with or without carriers and applies to the return transport of assemblies in the lower part of the system as well.

Multi Line also enables 3D solder joint inspection of THT assemblies during return transport. This means that a wide range of configuration and integration variants are available, allowing Multi Line to be customized to the specific process and production line layout.

Multi Line AOI THT

Technology Range

AOI PILOT Software

Multi Line is a common platform for a wide range of inspection tasks within the electronics manufacturing process. Depending on the configuration variant, the system can be used for solder paste inspection (SPI), for classic AOI applications of the SMD or THT process, and for conformal coating inspection (CCI).

The use of automated return of assemblies via a second-level transport conveyor has become commonplace in the THT process, this was also taken into account in the design of Multi Line. This return transport conveyor is an available option in the bottom section of the system.

Configuration example:

|

|

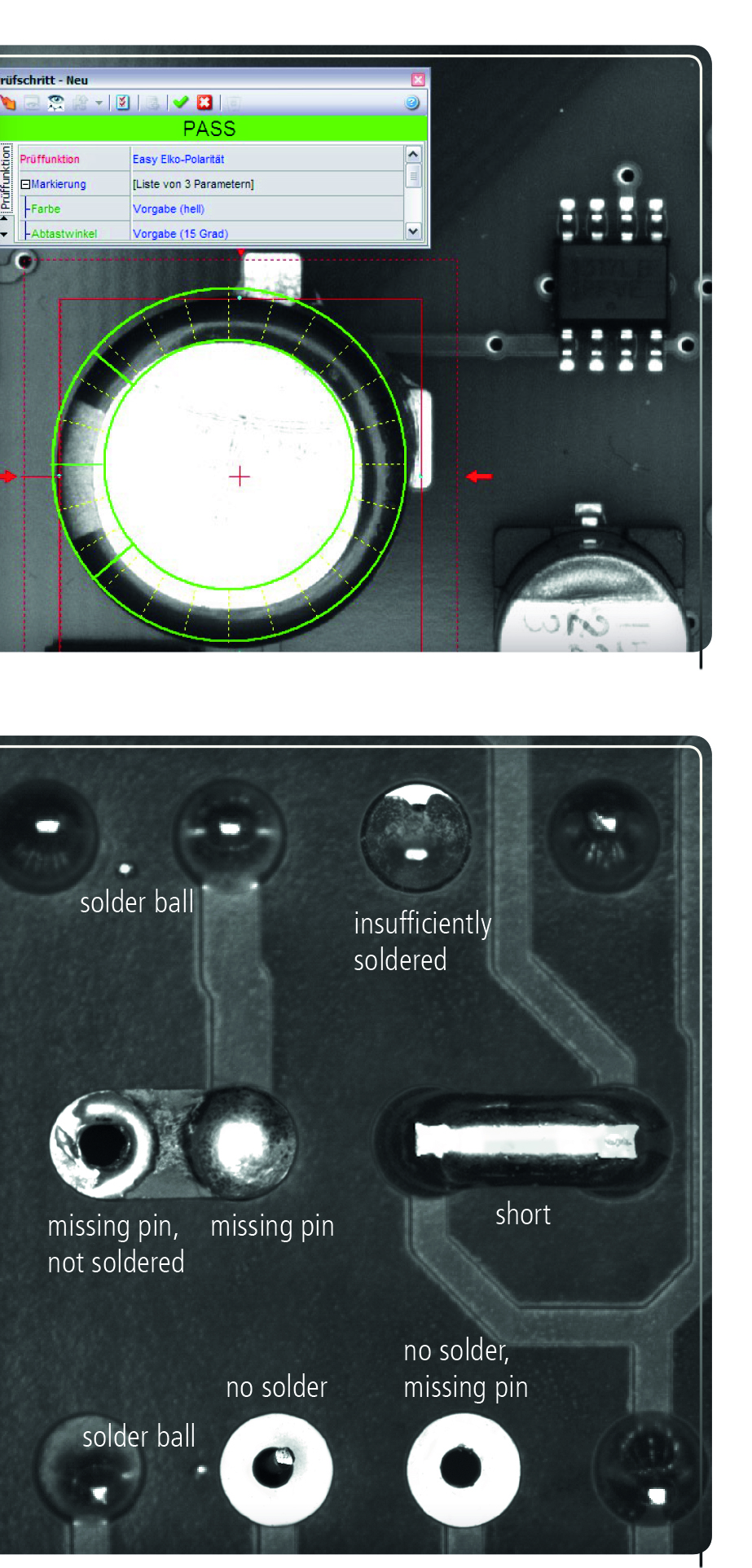

1. Polarity check at THTcomponents 2. Typical solder faults |

MAXIMUM FAULT DETECTION

• Unique multispectral illumination

• THT component, THT solder joint and wave-soldered SMD component inspection, coating inspection

• Freely configurable test functions and illumination opportunities

INTEGRATION OPTIONS FOR THT PRODUCTION PROCESS

• Manual or automated feeding via accumulating transport system

• Component side and solder side can be inspected at multiple positions within the production line

• Solder side inspection either on the upper conveyer belt or during the PCB return in the lower system area

SPEED ADVANTAGES OVER COMMON AOI SYSTEMS

• ”Flip free“ double-sided inspection of THT assemblies

• Multiple and independently working AOI modules in one system