1. **Automated Inspection, Reducing Manual Intervention**

Traditionally, the inspection and counting of components often rely on manual operations, which are not only slow but also prone to errors due to fatigue or human oversight. X-ray component counters automate these tasks, enabling fast and accurate completion while significantly reducing reliance on manual labor, thereby greatly enhancing production efficiency.

---

2. **High-Speed Processing Capability**

X-ray component counters can scan and count a large number of components within seconds, far surpassing the speed of manual operations. This is particularly important for factories with mass production, as it significantly shortens production cycles and increases overall output.

---

3. **High Precision and Reliability**

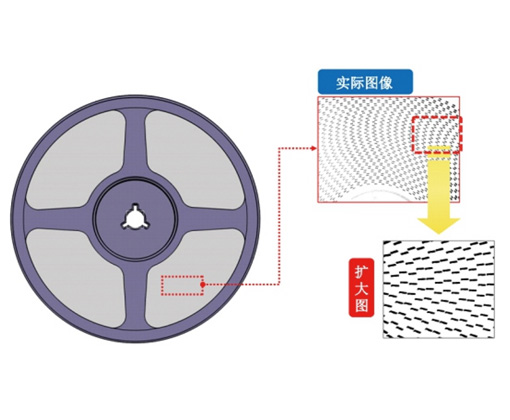

X-ray technology can penetrate components and generate high-resolution images. Combined with advanced image processing algorithms, it can accurately identify component types, quantities, and even defects. This high-precision inspection reduces error rates and avoids rework caused by missed or incorrect inspections, thereby improving overall production line efficiency.

---

4. **Non-Contact Inspection, Minimizing Damage Risks**

X-ray inspection is a non-contact technology that does not cause physical damage to components. This is especially critical for delicate components, such as semiconductor chips, as it prevents potential damage during the inspection process, thereby reducing scrap rates and improving yield.

---

5. **Real-Time Monitoring and Data Feedback**

Modern X-ray component counters are often equipped with data collection and analysis systems, enabling real-time monitoring of component quantities and quality during the production process. This data can be immediately fed back to production line managers, allowing them to quickly identify issues and adjust workflows, thereby reducing downtime and enhancing production efficiency.

---

6. **Multifunctional Integration**

X-ray component counters can not only count components but also perform quality inspections simultaneously, such as checking soldering quality and internal structural integrity. This multifunctional integration reduces the number of devices required in the factory, simplifies production processes, and further improves efficiency.

---

7. **Reducing Inventory Management Costs**

By enabling fast and accurate component counting, factories can better manage inventory, avoiding production delays or resource waste caused by insufficient or excessive stock. This helps optimize supply chain management and improves overall operational efficiency.

---

Practical Example

For instance, in an electronics manufacturing factory, X-ray component counters can be used to inspect the quantity and soldering quality of components on a PCB (Printed Circuit Board). Traditional methods might take hours to inspect a single PCB, whereas an X-ray counter can complete the task in just a few minutes while providing more detailed inspection reports. This not only accelerates production but also enhances product quality.

---

Summary

X-ray component counters significantly improve factory efficiency through automation, high-speed processing, high-precision inspection, and real-time data feedback. They reduce labor costs and error rates while optimizing production workflows and inventory management, making them an indispensable tool in modern manufacturing.

---

If you have further questions or need additional details, feel free to ask