Selecting a pick and place machine

A Pick and Place machine is the second step in a paste, place, reflow assembly operation. The “Place” function follows the “solder paste” function (stencil printer). The ‘place’ operation selects and delivers a component over the board and drops it into position. The simplest formof pick and place operation is by hand, that is, manually picking a component from a bin and, with the aid of a pair of tweezers and a magnifying glass, positioning it on the board and completing the operation with a hand-held soldering iron. This method works perfectly fine if you are only doing occasional boards. Other things to consider - the size of the components – (big or small) - affect the time required to hand place and solder. Fine pitch components are another issue, where more precision and accuracy are required, and the human factor comes into play. The work then become more tedious and time consuming. This article will focus on machine-assisted manual systems for users interested in going from a couple boards a day to much higher production volumes. Fully automatic systems are complex enough that we’ll need to devote a separate chapter to them.

PRODUCTION VOLUME

Let’s start by addressing production ranges for various types of machine assisted manual systems. For purposes of comparison, since all circuit boards vary in size and complexity, we’ll talk about volumes in terms of components per hour, or CPH. This will help you to decide what level of automation you’ll need.On the very low side of the scale -- using a manual hand system -- the only expense is the appropriate hand tools for nonmachine assisted manual placement At the high end of the spectrum, these machines are often modular or customized for high speed unattended operation.Buyers in this market are likely looking more at ROI than initial cost.

Manual and semi-automatic systems

A manual pick and place system is desirable for small, growing operations that need to increase their hand-held production volumes incrementally while also improving quality, thus reducing rework orrejects; however, the accuracy of placement is still limited by the capability of the operator.

Benefits of a machine-assisted manual system include:

• Less operator fatigue

• Fewer placement errors

• Better control

• Improved yield, less rework

| Type of System | Average CPH Range |

| Manual (Hand) | 0-50 |

| Manual (Machine) | 75-150 |

| Semi Automatic | 300-1,000 |

| Fully Automatic (Low Volume) Bench Top | 1,200 - 3,500 |

| Fully Automatic (Mid Volume) Free-Standing | 3,000 to 8,000 |

| Fully Automatic (High-Speed) Free-Standing or Modular | 12,000 to 30,000 |

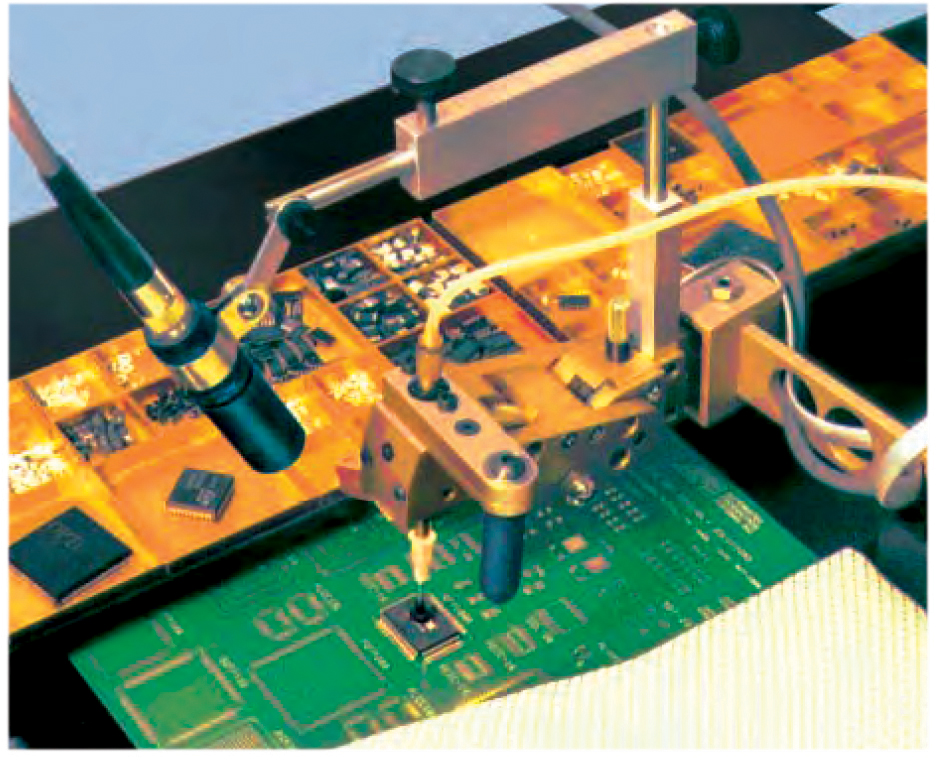

A machine-assisted manual system can be equipped with features such as an X-Y indexing table with vacuum pickup head or pen; ergonomic fixturing to help relieve operator fatigue; and additional fixturing for θ (rotation) and Z (height) positioning in addition to X and Y. Some machines offer an optional liquid solder paste dispenser, which is applied justbefore placing the component on the board if a stencil printer has not been used. Additional options include:

• Component Handling Trays

• Liquid Dispenser

• Tape Feeders

• Feeder Racks

• Vision Assist option

• Optional Stands

In most cases, machine assisted manual systems can be purchased with just the bare necessities, and desirable options can be added later as they’re needed.

Semi-automatic systems

Today there are very few semiautomatic machines still being made because of the increasing affordability of some of the more automated systems on the market. They were originally introduced at a time when the leap from manual to fully automatic systems was just too cost prohibitive and were made available with some features to assist the manual operation. More correctly referred to as “enhanced manual” systems, semi-automatic pick and place machines typically include a computer interface with a vision system that shows where the components go, but the placement itself is still done manually. This type of machine helps the operator position ultra-fine pitch components more accurately for low-volume applications, an operation that is very difficult to accomplish using a simple machine-assisted manual machine.

Ease of use

Most pick and place machines will handle afairly wide variety of board sizes, with a work table designed to accommodate boards up to 16” × 24”. There is also ease of control over the components, which aids in accuracy, along with a simple learning curve. In most cases, no training is required. Don’t overlook electrical requirements. Make sure the machine you buy will plugand- play in your environment without pulling in new wiring or else plan on an adapter/transformer.